By Terrence K. Cloonan, Lead Physical Scientist (CBRN)(Retired), Former U.S. Army Chemical Corps/CBRN Major, CM, RA

What is a multi-threat environment? It is a hostile situation where soldiers or responders must successfully react to any multitude of threats that present themselves. This requires suited-up responders to scan, identify, adapt, overcome, and mitigate the threats from active shooters, roque vigilantes, clandestine terrorism, or brazen force-on-force adversaries. To succeed in a multi-threat environment operators must either avoid it or wear personal protective devices capable of offering protection against a plethora of different toxic agents. The protective ensembles must offer a minimum-to-maximum level of protection that is live-agent tested against representative challenge agents covering an array of multiple threat compounds consisting of chemical warfare agents, toxic industrial agents, biotoxins, and viral contagions. Simulants are not live agents. The multi-threat live agents may present themselves as unitary or binary agents in a hospital, a terrorist attack site, or on a battlefield.

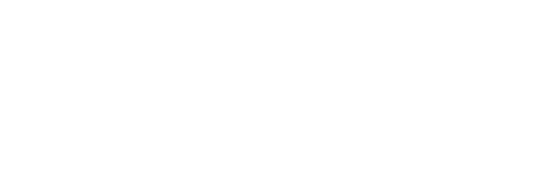

Chemical, biological, radiological, and nuclear (CBRN) multi-threat agents of concern are GB, VX/VR/CVX, HD, FGA, Fentanyl, SARS-CoV-2, Ebola/EVD, QNB, Ricin, and Cyanides. See Table 1 titled Decon of Multi-Threat Agents, Group 1 Chem-Bio, for a working list of agents, decon, rinse times, & rinsate guidance.

The U.S. public health doctrine for the removal of such agents is to apply copious amounts of pH-balanced soap and water rinses. But FGA requires next-generation decon methods consisting of proprietary dry powders supplemented with liquid base and acetate solutions used in a spray, blot, and dry-wipe method. The dry method still allows for warm soapy water rinses, as necessary. Soapy water relies on the universal solvent-water! While the proprietary decon powders rely on exact spot decontamination.

The use of the words “multi-threat”, as adjectives to describe the capabilities of a dermal protective suit, are merely a play-on-words designed to present a sales & marketing all-hazards quality to suit materials sold to emergency responders. The U.S. DHS 2019 lexicon does not have a standing definition for multi-threat or multi-threat environments. Nevertheless, a responder can face multiple like or different CBRN threats to their respiratory, dermal, auditory, and ocular senses during a size-up and mitigation of an incident response. Suits, gloves, boots, and respirators that can provide a multitude of protection capacities, while remaining pliable, easily deconned, and removable, will always be in demand. Even when such equipment is replaced by robotic automation devices or next-generation personalized protective biosystem ensembles. Anyone who has worn MOPP-4 for four continuous hours or spent a day in a “plastic suit” or JSLIST to complete live agent training knows there are select parts of your body that need fresh air that can cool you down while you are in a protective posture. Just the simple act of allowing your wrists to feel cool air for 5 minutes helps a responder to cool down and stay alert while suited up. It is difficult, if not impossible, to do that in an NFPA 1994 rated Class 1, 2, or 3 suit. Next-generation personalized protective biosystems (PPB) will attempt to unburden the wearer from such heat buildup issues while still effectively providing full-spectrum response capability to a toxic release.

Decontamination is the process of removing or neutralizing industrial hazardous materials, CBRN agents, or dangerous goods from contaminated people and/or equipment during a public safety incident or industrial workplace event, per the US DOT Emergency Response Guidebook (ERG) 2020/2021. The ERG also calls out four kinds of decontamination procedures for emergency responders, citing the NFPA 472 standard: 1) gross decontamination, 2) technical decontamination, 3) mass decontamination, and 4) emergency decontamination. Clean water or soapy water is used in all four of those described decontamination procedures. Soapy water has been a mainstay of chemical warfare agent decontamination since the introduction of US Army Field Manual No. 3-5, NBC Decontamination, published June 24, 1985. FM 3-11.5, dated April 2006, replaced FM 3-5, and it was a doctrine mainstay for military CBRN decontamination until it was superseded by ATP 3-11.32, effective 9/9/2021. Water and soapy water decontamination compounds are still mainstays in those civil-military operations. The soapy water images in this paper are from a fire service technical decontamination quarterly training exercise conducted on July 15th, 2021.

The exercise allowed the use of OSHA/EPA Level A and B suits plus NFPA 1994 Class 1, 2, and 3 suits together in a technical decontamination training drill. Suits undergoing chemical warfare agent decontamination are rarely reused. A real-world large-scale release will cause a re-think of that. NFPA 1994 garments are likely to retain chemical weapons liquids in the cloth material surfaces of the garments. Whereas a “plastic suit” material of a Level A or B ensemble will allow the liquid agent to run off. And the high cost of such NFPA rated suits would cause one to consider reusing the expensive NFPA 1991, 1992, 1994, or 1999 standard-rated garments. Just as filtering facepiece respirators (FFR) offering NIOSH N95 protections had to be re-used during the COVID-19 pandemic, CBRN respirators like SCBAs and PAPRs will also be in short supply during a real-world incident response and are expected to require scientific re-use methods to extend their in-service life. None of these reuse methods would be viable without prior knowledge of the respirator and suit manufacturer’s user instructions (UI) for the items. These UIs are not published in a common standard format between different suit manufacturers or respirator manufacturers. The current suit UIs and respirator UIs do not sufficiently address the unique interface requirements of a donned respirator sealing to a suit hood butyl orifice opening. A field-expedient water shower check of the hood-to-respirator seal is highly recommended when relying on a hooded suit flexible orifice for liquid-gas-vapor tight interface with a full-face, tight-fitting respirator face blank of a self-contained breathing apparatus or an air-purifying negative or powered air respirator.

Technical decontamination of entry responders requires a seasoned and alert OSHA 1910.120 trained technician-level decon line worker. Normally that worker is in the same respirator as the entry responder and maybe in the same dermal protective posture or a step lower. Here you see a Level B decon worker applying soapy water to a Class 1-1994 outfitted entry responder. Note the hood butyl seal flexing against the SCBA facepiece. Both responders are in Level B? If you were to equate the civilian PPE levels to military mission-oriented protective posture (MOPP) levels, do not do it. MOPP-1, -2, -3, & -4 are designed to protect soldiers in less than IDLH conditions and rely solely on air-purifying respiratory protection. A self-contained breathing apparatus (SCBA) is not part of MOPP decision logic. However, special operators have the flexibility to integrate any level of a compliant respiratory protective device into MOPP as they deem necessary. Civilian responders do not use MOPP. They use Levels A, B, C & D. A Rethink Level A white paper, accessed on November 1st, 2021, answers twelve questions on the modernization of civilian HAZMAT PPE. While MOPP gear is not addressed in this rethink level A paper, OSHA/EPA Levels A, B and C are. OSHA 29 CFR 1910.120 does require Level A for responses to known concentrations of HAZMAT.

Responders and soldiers must balance the use of DOD military specified and OSHA/EPA compliant protective suits with aging and current National Fire Protection Association (NFPA) 1-9-9-4/1994 standard-compliant garments and vetted required components. Here you see a fire service responder undergoing soapy water technical self-decon. He is in a mitigation shower tent wearing an OSHA/EPA Level A totally encapsulated ensemble with CBRN SCBA on-air, as the last line of respiratory defense. The SCBA is expensive and is “shielded” from external physical and chemical contamination as well as having some protection from abrasion. Moderate abrasion that could break the facepiece-to-human face seal and allow exposure to toxic contamination, making such “balancing” impossible. All SCBAs, open-circuit and closed-circuit models, are not shielded when NFPA 1994 garments are worn.

“Do not fix it, if it is not broken!” The use of cold or warm soapy water and soft bristle brushing are the minimum public health requirements for individual or technical decontamination of chemical warfare-terrorism agents. We know, without a doubt, that soapy water and brushing allow the start of physical removal, dilution, and neutralization actions of surface contamination in a timely and efficient manner. There is a reason why they are still the most common tools for lifesaving individual/mass casualty decontamination and equipment clearance – soapy water does not physically harm the responder being decontaminated or the person, or robot, doing the decon work.

Most likely, if you are undergoing technical decontamination, as a lone responder or part of a two-man team, that normally means you have accomplished the assigned mission and have the potential to be contaminated, but not exposed…. or are exposed and are undergoing acute or systemic agent effects with or without your knowledge while suited up. Here is where a second responder of a two-person team becomes vital. Ideally, entry responders operate in teams of two. So going through any type of “decon” the two-man team should not be separated. The reason is so that each one can observe the other and look for indicators of protective equipment compromise or MAYDAY requirements. Live agent training (LAT), at key national and international laboratory-style training sites, has shown that personal protective barriers worn in such “COBRA” training facilities can fail in any number of areas. The fingertips of protective gloves can rip slightly. The user’s respirator face seal can break while handling casualties giving a shot of cool air to the user’s face. Followed by a recognition that the seal has broken and a hope that it will do as it is designed and reseal itself without going thru user seal checks. Or you may be observing your suited up subordinates and you see one with moisture building up in the eye lens area of his/her respirator. You know from experience that is an indicator of a face seal leak in an APR. You can take corrective action or increase localized monitoring of that person. In such actual or training reality situations, what you do not want to do is exceed the use limitations of the protective equipment.

An excessive use limitation example would be to physically place your “air-purifying respirator worn face” over a localized IDLH toxic vapor source — like a plate of liquid GB being bleached. That bravado move got the instructor an actual or potential IDLH level localized exposure while wearing a mil-spec APR designed to only protect him against field concentrations of CBRN agents. NIOSH-approved CBRN APR and tight-fitting CBRN PAPRs offer escape capacities inside the canisters for a single-use level of protection against a CBRN IDLH concentration. But only one time, with the intent to allow you to walk away/escape from the source. Such escape respirators were used on January 6th, 2021, in Washington, D.C. Do not take this lightly! You can die a slow death from the acute or cumulative effects of live-agent training just as easily as dying from a mistake made during United Nations site exploitation missions.

Wash responders from head to toe. Here you see soapy water ladened, encapsulated Level A responder holding his hands up at eye level. Now look at his eyes and you can see he is staying focused on the next step ahead by looking through a panoramic suit visor worn over top of a tight-fitting, full-face panoramic facepiece of a NIOSH-approved CBRN open-circuit SCBA. Visual acuity is so good that you can see the lettering of “Dailey” on the facepiece. OSHA/EPA Level A ensembles offer some of the highest levels of wide-angle viewing of any protective dermal suit while protecting the SCBA respirator being worn and thus the total health of the wearer. And as you know, when you are in level A it helps to have a hand towel inside the ensemble so you can pull an arm out of the suit sleeve and wipe down the interior surface of the suit visor. The action wipes away the accumulated SCBA exhalation breathing air compounds as well as the built-up exhaled human water vapor moisture. 1994 suits vent to open air.

On August 10th, 2021, I had the pleasure of reading a fire service decon plan and observing a Dahlgren Decon demonstration done inside a trailer on Randalls and Ward Islands. The two-man demonstration team relied on the manufacturer’s Enhanced Decon Systems (EDS) job guide, not the app, to display the 4.5 stations technical decon line.

It was a decontamination platoon leader’s happy dream watching the EDS Part A, Part B1, and Part B2 chemicals opened and prepared. Canadian RSDL is also part of the EDS process and is vital for skin decontamination to the lowest level achievable. This is where you ask, “how clean is clean?” for the RSDL efficacy.

All of these decon agents require defined contact and dwell times. It takes a fifteen-page EDS Job Guide, or the Dahlgren Decon (DD) digital app, to understand the deployment of any size package of EDS products purchased. The DD EDS process is a complicated decontamination method and will likely need a dedicated technician to manage the use of the Parts A, B1, & B2, and RSDL decontamination agents, with assorted tactical sprayers, fibertect pads/mittens, drop bags, fibertect foot sump pads and 22-ounce RTU packets designed to support a processing capacity of EDS6, EDS12, and EDS24. A peer-reviewed publication on DD performance is in an EPA/Battelle presentation titled “Decontamination Options for Sensitive Equipment-Related Materials Contaminated with Persistent Chemical Warfare Agents, by Lukas Oudejans, David See, Carisa Dodds, and Anthony Ellingson, dated May 8-10, 2018.

On October 14th, 2021, I spoke with the DD PM over the phone. I explained I had just seen a DD demonstration in August and was curious what other civilian municipalities were actively using DD. I was told a select IRF of CBRIF had adopted DD, and that civilian responders of the DC NCR COG were all active users, as well as San Francisco PD, Chicago FD, and FDNY. Follow on R&D is focused on a D&D hand soap bar for surface decontamination, not for cleaning wounds. SARS-CoV-2 LAT had not been done yet. In closing, it was stated that DD items are listed on the FEMA Authorized Equipment List (AEL). However, an online search done on November 18th, 2021 for Dahlgren Decon solution or method in the FEMA AEL database produced no results from the following link.

Regarding the CY 2020 fire service decon plan read, it is broken down into 9 sections: decon corridor setup; persistent liquid chemical VP < 150 mmHg; solid chemical; chemical, gas or liquid w/VP > 150 mmHg; biological agent/fentanyl; persistent chemical warfare agent; radioactive material; decontamination solutions; and decon kit contents. I expect it will be updated with new DD methods. But all the DD solutions used, and all the soapy water sprayed on contaminated personal protective equipment (PPE) can only do so much. They have a low efficacy when just sprayed on and even a lower efficacy when the toxic agent forms a film on the PPE surface. This is when brushing, coupled with soapy water, must be done to loosen up the surface contamination and allow it to be physically removed or flow away in the soapy water run-off. One way to evaluate decon method efficacy is to apply low quantities of a fluorescent non-toxic simulant to the PPE, prior to the start of decon. Glo-Germ was applied to the wrists and ankles of two NFPA suit-clad responders during the July 15, 2021 exercise. A follow-on full tube UV-A blacklight exposure showed the areas of Glo-Germ remaining as being a qualitative 50-60% removal rate while select areas that were not rigorously scrubbed with a brush were “glowing”. The UV-A images below show white particulate Glo-Germ still present on items of PPE.

None of these observations would have been possible without the support and interest of the responders shown in these images. Here you see two decon lane workers processing an entry-level responder through the first station of a deliberate technical decontamination line. Note the open-air exposed man-packed SCBA respirators, the fluorescent green Level A suit with double gloved chem taped suit-glove interface, a chem taped orange protective boot-suit pant leg interfaces, and a large side front entry zippered area of the suit with an expanded backpack cover over the worn SCBA with a suit designed supplied airline respirator hooded pocket. The gray-black suited responder on the left is wearing a search and rescue style safety helmet over an NFPA 1994 Class 3 garment with a NIOSH-approved CBRN SCBA. The tan suited responder on the right is wearing an OSHA/EPA Level B compliant suit with a safety helmet, NIOSH-approved CBRN SCBA, and chem taped glove interfaces. His boot-to-suit pant interfaces is not chem-taped over. This image replicates the first rinse step depicted in the 5th column of Table 1 discussed. It is essentially a scaled-down version of post 9-11 era fire engine gross decontamination operation for mass casualties, but with a single-entry responder processing through a high-pressure-low volume clean water spray wand that allows localized contamination avoidance. All done in an open-air, downwind direction, pop-up single tent in a double enclosed mini-sump portable ground platform that allows safe processing of “dirty” responders, while controlling toxic runoff from soapy water application steps. Toxic agent concentrations are diluted by soapy water but remain toxic. Therefore, the decon rinsate must be handled as hazardous waste and cleared appropriately.

A responder wearing an NFPA 1994 Class 3 compliant suit with a NIOSH-approved CBRN SCBA for situations where the dermal threat is low, but the respiratory threat is high. Normally, NFPA 1994 Class 3 suits are matched up to NIOSH-approved CBRN APR or CBRN PAPR to maintain NFPA compliance. Another key observation not always easily seen is the entrapment of an SCBA neck strap inside the suit.

As shown above, the neck strap entrapment must be detected by a second person or the other member of a two-man team. To remedy the PPE use issue, the user must doff the donned the suit, pull out the neck strap, and re-don the suit and its hood orifice seal to the respirator. If you did not know any better, you would not know that the entrapped neck strap creates a liquid and vapor seal “break” or visible gap between the suit hood orifice and the donned respirator facepiece. The way to fix this gap is to doff the hood, pull the neck strap out and then remove it completely or just leave it on the outside of the suit to absorb contamination-not! In the two blue suit pictures you can see how the SCBA neck strap was pulled out of the suit, the SCBA was redonned and the suit was re-zippered and then re-sealed to the face blank by an assistant. The last two images are from observing a November 1st, 2021, suit manufacturer demonstration to a city hazmat team audience. There is a need for suit and respirator manufacturers to work together, as well as for each PPE manufacturer to provide clear information on what type of respirator matches up to what type of NFPA rated suit and vice versa. Additionally, the suit manufacturer instructors must be familiar with what NIOSH-approved CBRN respirators are in the public safety agency inventory and know if those respirators are the same respirators listed on the Intertek/Safety Equipment Institute (SEI) webpage listing for compliance to the stated NFPA standard. Suit manufacturers’ representatives also need to have a working knowledge of respirator neck straps and other required or accessory style components and how the wearing of them impact the correct use of the marketed suit.

In conclusion, multiple topics have been addressed concerning soapy water decon. Such topics as what a multi-threat environment is, what are multi-threat agents, how multiple agents can be grouped under a hastily termed “Group 1 Agents” table showing recommended decon rinse times per agent type and soapy water decontamination solutions. How military decontamination doctrine, individual MOPP levels, technical decontamination actions, OSHA/EPA Level A, B, and C protective postures, and the use of NFPA 1994 Class 1, 2, and 3 protective ensembles complement each other. And how next-generation decontamination methods using Dahlgren Decon EDS6/12/24 can improve decon while the application of non-toxic Glo-germ particulates to equipment can aid in the visual evaluation of any decontamination agent’s efficacy. With these topics in mind, how vulnerable is a civilian population to a deliberate chemical warfare weapon attack or terrorist grade chemical agent attack? Just look at current-day news telling us about the use of isolated chemical warfare agent attacks on solitary civilians. What local car washes, swimming pools, large parks, and school football fields can be used to conduct field-expedient decon operations of civilian casualties? Many of them. Hopefully, soapy water solutions are in every working person’s reach. Such answers need to be addressed and response plans need to be dusted off or created and briefed to responsible citizens. Better to have some sort of plan, than to have no plan at all. One might conclude that civil support teams (CSTs) need to train civilian “civil defense corps” in each city to support survivability in a time of chemical mass casualties, radioactive fallout from weather-related accidents, or isolated vigilante terrorism using bear agent repellant and handheld weapons. As we know, most civilians are not taught to recognize and escape a chemical warfare attack or industrial chemical release. And public safety responders do not carry personal decontamination kits on their work belts, but they do carry Narcan, egress rope systems in their cargo pockets, and SCBAs on their trucks. Surviving a chemical warfare attack is contingent upon public safety responders and 911 call centers being able to recognize such an attack, set up command posts upwind of such events, take individual protective actions, a soak-up visible toxic agent from skin and equipment surfaces, and rapidly move targeted personnel away from the chemical attack scene, while not spreading contamination. Good Luck!

Resources

1. Lion, Ready for Action ChemBio Garments sales pamphlet, dated 10/2019.

2. Rethink Level A, Assess. Select. Deploy. Two-page pamphlet. Emergency Response Tips and International Personnel Protection, Inc., undated. Accessed on November 1, 2021.

3. EDS Enhanced Decon Systems Job Guide, First Line Technology. 15 pages, undated.

4. U. S. Department of Transportation 2020 Emergency Response Guidebook, 202-366-4900.

5. FDNY HAZMAT Operations Technical Decon Manual, Dec 2020-Revision. Accessed on 8/10/21.

6. Chemical Warfare Agents, Third Edition, Biomedical and Psychological Effects, Medical Countermeasures, and Emergency Response, Edited by Brian J. Lukey, James A Romano, Jr. and Harry Salem, CRC Press, Taylor and Francis Group, Copyright 2019. Purchased on June 24, 2021.

7. NIOSH/OSHA/ USCG/EPA Occupational Safety and Health Guidance Manual for Hazardous Waste Site Activities, DHHS (NIOSH) Publication No. 85-115, dated October 1985.

8. NIOSH Pocket Guide to Chemical Hazards, DHHS (NIOSH) Publication No. 2005-149, Sept 2007.

9. Lion Apparel User Instruction, Safety and Training Guide for ERS NFPA 1994 Class 3 Ensemble, dated April 2010.

10. Guideline for the Decontamination of Chemical Protective Clothing and Equipment, AIHA Guideline 6-2005, October 2005.

11. Fire Department of New York-an Operational Reference, Twelfth Edition, FDNY Foundation, Copyright 2020 by James S. Griffiths. Accessed on August 10, 2021.

12. HQ, Department of the Army, Field Manual 3-5, NBC Decontamination, June 24, 1985.

13. Army, Marine Corps, Navy, and Air Force CBRN Decontamination, Multiservice Tactics, Techniques and Procedures for Chemical, Biological, Radiological, and Nuclear (CBRN) Decontamination, Field Manual 3-11.5, April 2006. Superseded by ATP 3-11.32, eff 9/9/21.

14. Kappler User Information for Durachem 500 Protective Ensemble for Hazardous Materials Emergencies and CBRN Terrorism Events, RM # 31655, Rev 4-2019. Accessed on March 24, 2021.

15. CDC Emergency Response Card, GB, VX, HD, Fentanyl, EVD, QNB, Ricin, and Sodium Cyanide.

16. Presentation titled Decontamination Options for Sensitive Equipment-Related Materials Contaminated with Persistent Chemical Warfare Agents by L. Oudejans, D. See, C. Dodds and A. Ellingson, EPA and Battelle, May 8-10, 2018.

17. DARPA Broad Agency Announcement # HR001120S0015, dated November 26, 2019.

18. Next Generation Nerve Agents: Symptoms, Treatment and Lessons Learned, HHS ASPER Tracie, 2019. Accessed on November 17, 2021.

19. Fourth Generation Nerve Agents, a scientific presentation at the ACMT, Haifa, Israel, by Charles McKay, MD, November 19, 2019, accessed on November 3, 2021.

20. CBRN Respiratory Protection Handbook, DHHS (NIOSH) Publication No. 2018-166, July 2018.

21. Safety Equipment Institute (SEI) Certified Product e-List accessed November 22, 2021

Photography credits: All responder photography images were taken and cropped by Terrence K. Cloonan, July to November 2021, in conjunction with the Allegheny County Hazardous Materials Coordinator, the City of Pittsburgh HAZMAT Team, and the City of Pittsburgh Fire Academy, Pittsburgh, PA. The three UV-A images are the sole property of Terrence K. Cloonan. The Kappler. Blauer, and Lion 1994 suits shown were under field-use observation trials July to November of CY 2021.

Disclaimer: The mention of any company or product does not constitute an endorsement of said product. In addition, any citations to public facing websites or publications do not constitute endorsement of the organizations, programs, authored publications, or products by the author of this paper.

About the Author

Mr. Terrence K. Cloonan is an adaptive leader who has been passionately involved in nuclear, biological, and chemical offensive and defensive (CBRN) operations since his days as a U.S. Army ROTC cadet in 1978. Not a stranger to military or civilian helicopters, this guy spent five years in the 101st Airborne Division (Air Assault), Fort Campbell, KY and was a chalk leader of a stick that air assaulted into hostile Iraq on a CH-47 helicopter during Desert Storm. His work with the 101st Aviation Brigade led to the publication of novel aviation rotary wing decontamination procedures published in FM-3-5. Here you see him double masked-up and flying over the Grand Canyon, Arizona, this past July of 2021.